► No wearing parts (carbon brushes, commutator, field coil)

► Our original compact controller

The brushless motor offers a significantly extended product life cycle by eliminating trouble including armature burnout, layer short or commutator wear even in severe work environments. Besides, no carbon brush replacement is required.

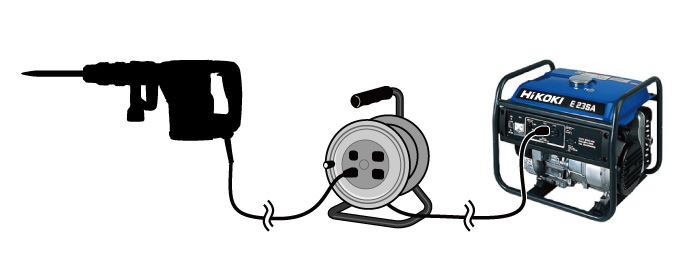

Equipped with Our original, compact high efficiency inverter circuit, the demolition hammer works with an engine generator that doesn't have an on-board inverter.

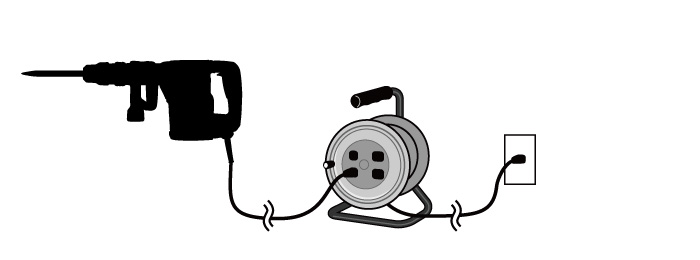

The brushless motor runs cooler, and its performance isn't affected as much by voltage drop from long extension cords onsite. This vastly improves electrical efficiency.

Our original, spring-type dynamic vibration absorber with a weight and two springs move in the opposite direction to the vibration direction of the main body. This results in reduced vibration and improved operating efficiency.

Our original vibration-absorbing mechanism with the Transatory unit (rubber dampers) and the hinge unit provides high vibration absorbing effect. This will help absorb and reduce vibrations to the user, making it more comfortable for prolonged periods of time.

makes the housing more rigid, significantly enhancing durability of the motor unit.

1. Push-button, constant speed control with variable speed

The built-in electronic control circuit adjusts the impact rate according to applications, and the four-step impact rates can be selected by the impact rate selector switch.

| Display Lamp |  |

|

|

|

| Full Load Impact Rate |

1,430/min | 1,900/min | 2,370/min | 2,850/min |

|---|

2. Power Lamp

lights up when the plug is inserted into an outlet.

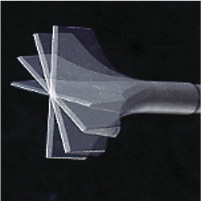

A bit can be mounted by simply inserting it into the tool holder

The tool bit angle can be easily adjusted to 12 different angles every 30 degrees by turning the grip.

Large easy-to-grip trigger switch for more control.